- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Heat Exchanger Manufacturers/Suppliers/Exporters in Pune

Perfectplus Engineering India Pvt. Ltd. has been manufacturing Heat Exchanger for more than 8 years and has a wide range of products to choose from. We Heat Exchanger manufacturers, suppliers, and exporters in Pune are known for the standard quality products that are designed with the latest technology and best engineering practices.

We have been providing customers with high-quality heat exchangers and other products since its inception in 2014. The heat exchanger in Pune has established itself as a reliable partner to both domestic and international clients. Our team of experts offers various services such as engineering design, technical support, manufacturing assistance, etc.

We Heat Exchanger manufacturers, suppliers, and exporters in Pune have been able to deliver on its promises to its clients by providing them with high-quality products at competitive prices.

Description: Heat Exchanger

Heat Exchanger is a device that transfers heat from one place to another. It is used for different purposes like heating, cooling, and industrial purposes. It transfers heat from one place to another by using a fluid as a medium. The fluid boils at the cold end and evaporates at the hot end.

It is usually made of copper tubing that is sealed inside a metal casing with fins on the top and bottom. These fins help maintain a constant flow of air through the system by taking advantage of the natural convection process.

There are two different types of Heat Exchangers:

- External Heat Transfer Devices (EHTDs)

- Internal Heat Transfer Devices (IHTDs)

Properties:

Industrial Heat Exchanger is a product which changes the temperature of fluids by exchanging thermal energy between them.

An heat exchanger is typically made of a tube that has an inside surface with a temperature difference from the outside surface. The fluid flows through the tube and across the inside surface, where it is cooled by the cold fluid on the outside of the tube.

One of the key features of a Heat Exchanger is that it has a closed loop. This means that the fluid is constantly moving back and forth through the heat exchanger. It also has two pipes called inlets and outlets which are connected by a pipe called an intercooler.

Uses-

Heat Exchanger is used in many industries like oil and gas, chemical, power generation, water treatment, and many more. It can be used for heating, ventilation, and air conditioning purposes as well as for industrial purposes. They have wide applications in various industries such as oil refinery, water, steam, chemical plant and power plant.

Our shell and tube heat exchangers are used in many comfort and industry applications for heating and cooling fluids. They consist of a shell with traditional plain tubes or enhanced surface tubes for high thermal performance. The fluids can be liquids or gases, one of which flows inside the tubes while the other flows outside the tubes within the shell. There are single-phase or two-phase heat exchangers, and the latter is used to either boil or condense fluids.

| Usage/Application | Industrial |

| Material | MS, COPPER AND STAINLESS STEEL |

| Brand | Perfectplus Engineering India Pvt. Ltd. |

| Medium Used | OIL, WATER & AIR |

| Country of Origin | Made in Pune |

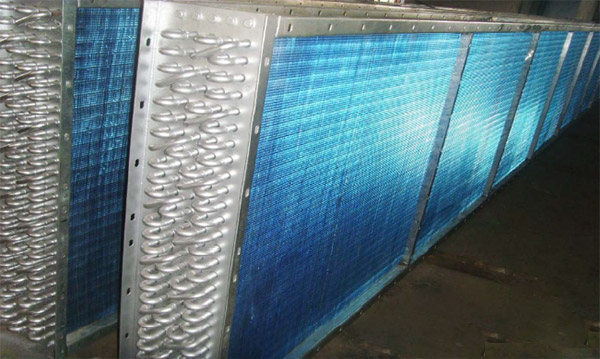

FIN AND TUBE HEAT EXCHANGER / RADIATOR

The obvious advantage of Air cooled fluid cooler is that it does not require any water after its first charge. This is completely a closed circuit system. The hot fluid (water) from the source is made to pass through finned surface heat transfer coils & using the heat is rejected to ambient air passing through coils using axial fans.

AIR COOLED HEAT EXCHANGER

| Cooler Material | Steel |

| Type | Air-Cooled |

| Application | Hydraulic and Industrial Process |

| Cooling Type | Air Cooled |

| Country of Origin | Made in Pune |

TRANSFORMER RADIATOR

The plant have a capacity to manufacture the radiators with fin width of 226mm, 300 mm & 520mm having a pitch of 50 MM. Length of fins varies from 400 to 4000 MM in steps of 100 MM & assemblies of 2 to 30 fins, as per customer’s requirements.

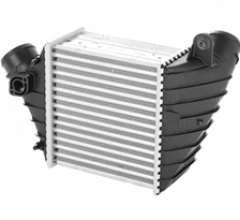

INTERCOOLER

The intercoolers (Charge Air Coolers) are designed to reduce fuel consumption while increasing the engine power and efficiency. The intercooler’s task is to reduce the temperature of the inlet gas and thus densify the air required which optimises the combustion. The intercooler lowers the temperature of the inlet gas from 130° C to 60° C, removes the negative effects of the turbo and increases the power by around 20%.

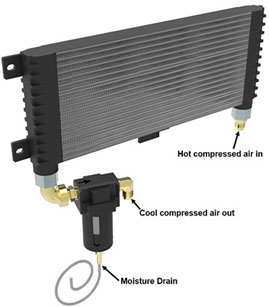

AFTERCOOLER

An aftercooler is a mechanical heat exchanger designed to remove the heat-of-compression from a compressed air stream and to condition the air so it can be used in air-operated equipment.

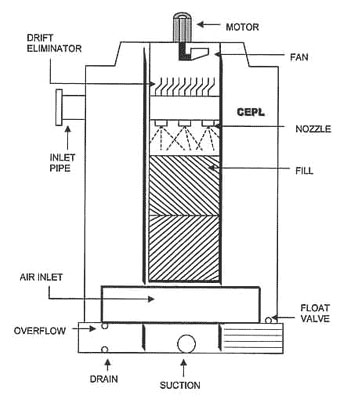

FRP COOLING TOWER

These Cooling Towers are primarily supplied in Fibreglass Reinforced Polyester (FRP). Structural design for operational load and wind pressure of 30 psf. is taken into consideration. Details provided on request for quote.

AHU COILS

We are among the reputed organizations, highly engaged in manufacturing and supplying an optimum quality range of AHU Coils.

Specifications:

Available in various sizes as per clients' requirements

Widely used in industrial water cooling systems

TUBE BUNDLE

A hot fluid is pumped through the bundle in a straight line from one end of the outer casing to the other.

To determine the number of tubes in this tube bundle, simply count the tubes manually.

This configuration is often popular because it involves lower installation costs.

How do you Clean Tube Bundles?

Tube bundles are easy to clean.

To clean tube bundles, you must remove them from inside the heat exchanger system.

You then clean the inside and exterior surface using suitable fluids before returning them back the device.

Cleaning of the tube bundles is possible if done chemically.

You can flash the chemical cleaning agent at high pressures directly into the inner walls of the tube bundles.

It removes any residues which could have stuck to the component.

Following this, you rinse the tubes very well so that it is clean before operation reconvenes.

In the event that there are leftover residues, the damage can be destructive to the material of construction as well as potentially contaminate the fluid/product.

Similarly, you can clean the insides of the tube bundles mechanically.

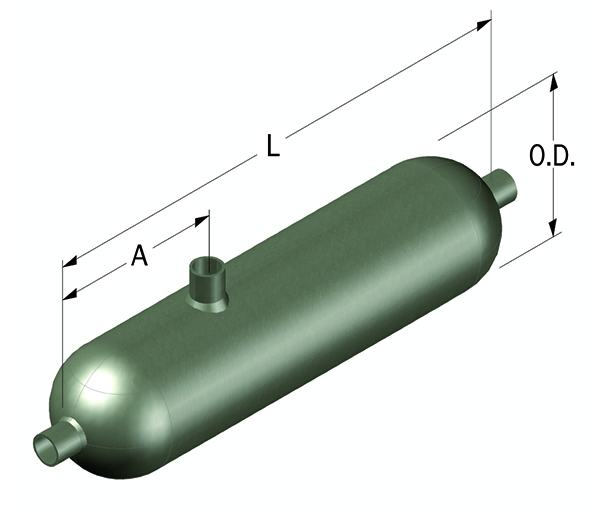

CONDENSATE SEAL POT

Condensate chambers, also known as seal pots and condensate drip pots, are welded pressure vessels that allow instruments and valves to be attached in line with routed tubing to allow for line sampling, elimination of fluid, and other processes. They are used to protect sensitive metering systems and devices by trapping and holding condensate and foreign material that may accumulate in gaseous service lines.