- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Flow Transmitter Manufacturers/Suppliers/Exporters in Pune

Perfectplus Engineering India Pvt. Ltd. is a leading company in the field of Flow Transmitter manufacturers, suppliers and exporters. We Flow Transmitter manufacturers, suppliers, and exporters in Pune are one of the most trusted brands in Pune and have a strong presence across the globe.

The Flow Transmitter in Pune has been manufacturing and exporting high-quality, latest designs, and an affordable product range of Flow transmitters since the year 2014. We have an experienced team that offers you excellent customer service and supports you with all your needs.

Our team has years of experience in the industry that has helped them grow into a reputable company with high-quality products and the latest designs. The flow transmitter’s raw material must be able to withstand high temperatures without melting or degrading, it must be corrosion-resistant, non-flammable, non-toxic, non-conductive and non-magnetic.

Introduction-

The flow transmitter machine is a device that regulates the flow of fluid from one point to another. It is usually called a pump or compressor depending on its application and it uses an impeller to move fluid from one point to another. It consists of a tank and a motorized pump.

Flow transmitters are designed for continuous operation with minimal maintenance requirements. They are used because they can be easily operated and maintained at high pressure.

They can be used to reduce the risk of explosion caused by the uncontrolled release of flammable gas and liquid. It also helps in preventing the fire from spreading to other areas by using forced ventilation. They can be found in many different shapes and sizes depending on the industry they’re used in.

Characteristic features-

A flow Transmitter is a machine that can be used to prevent and reduce the amount of water lost in industrial processes. It is a device that has been designed to optimize the process of water treatment, which is essential for the production of food, beverages, and other consumer goods.

It consists of a sensor probe that is inserted into the pipeline and connected to a computer or other measuring device. The probe sends signals to the computer or other measuring device which can be used to control valves on flow lines in order to control pressure, temperature, etc., as well as to detect leaks in pipelines.

Application:

Flow transmitters can be found in many industries such as mining, oil, and gas, chemical processing, pharmaceuticals, food processing, power generation, etc. They have been used for decades now but only recently have they become popular due to the increased demand for automation in industrial processes.

| Size Range | 1/4"... 2" NPT, 1/2"... 8" ANSI Flange |

| Connection Type | NPT Threaded or ANSI Flanged |

| Maximum Pressure | 230 PSIG (Optional 360 PSIG or 580 PSIG) |

| Maximum Temperature | 250 or 300°F, Depending on Model (Optional 530°F) |

GLASS TUBE ROTAMETER

When measuring liquid or gas flow at higher pressures and temperatures than is suitable for plastic, you can achieve accurate flow rates with robust glass tube rotameters (variable area flow meters) from Brooks Instrument. With a broader range of flow rates available, glass tube rotameters are suitable for a variety of liquids and gases.

Resistance to thermal shock, pressure and oxidation is the result of employing borosilicate glass tube bodies that can withstand pressures up to 13.8 bar (200 psi). Plus, corrosion-resistant material options for scales, floats, fittings and valves accommodate a variety of applications, whether in the lab or in industrial processes.

METAL TUBE ROTAMETER

Durable and accurate flow meters for fluid measurement in high-pressure and extreme temperature applications.

Armored to deliver repeatable, reliable flow measurement in demanding high-pressure, high-temperature applications, metal tube variable area flow meters from Brooks Instrument set the global standard for rugged durability and sustained accuracy.

Globally approved for use in hazardous environments, metal tube rotameter (variable area flow meter) manufacturer Brooks offers a range of metal tube rotameters that include corrosion-resistant options for metering aggressive fluids and multiple connection options to make it easier to interface our meter into existing industrial systems. Engineered for long-lasting performance, Brooks high-pressure water or gas flow meters deliver excellent meter repeatability to help accurately measure and precisely control complex industrial processes.

PURGE ROTAMETER

Process Control Devices offers a series of variable area flow meters in Mumbai. Designed to measures the flow rate of a fluid flowing through Vertical pipelines. Purge rotameter are cost-effective and convenient for low flow rate sign for fluids. Where operating conditions are with the limitations of Glass metering tube of rotameter. The float moves smoothly in an upward and downward direction in tapered Glass Tube with fluid flow from bottom to top.

The float takes up a position where buoyancy forces and the float weight is balance in proportion to flow rate. The top position of the float as indicated by scale is the measure of the instant flow rate. These also known as low flow rotameter. We provide flow calibration report with each rotameters with one-year validity. It is being used for purging / isolating or controlling of fluid passing through process pipes. We manufacture purge rotameter with a vertical connection, rear connection and offsets connection with isolation valves. This is also known as low flow rotameter.

BY-PASS GLASS TUBE ROTAMETER

We offer Bypass Glass Tube Rotameter.

Specifications:

Description: As per enclosed catalogue with MS flanges, SS orifice, SS pipes & SS valves

Metering glass tube rotameter: By the side

Floats: SS

End Fittings: 6” MS powder coated Flanged connection

Range: 0 to 300 M3/Hr.

Applications: For Furnace oil 380 cst

Operating temp: Max 100 deg C

Operating pressure: Max 10 Bar

Make: Ji

Accuracy: +/- 2% FS

BY-PASS METAL TUBE ROTAMETER

| Rangeability | 7 1 or 5 1 |

| GTR Type | 101 |

| Orifice Plate | 316 SS, Ebonite 'C' |

| Accuracy | 2% of Full Flow |

| Pipe line | 316 SS, Mild Steel/Cs. |

| Carrier Rings | 316 SS, Mild Steel, Cs. |

ACRELIC BODY ROTAMETER WITH OR WITHOUT ISOLATION VALVE

We are a unique name in the industry, devoted towards offering the best quality range of Acrylic Body Rotameter with and without Isolation Valve.

| Fluid | Liquids and Gases |

| Density Sp Gravity | Up to 1.85 |

| Viscosity | Below 100 cp |

| Desigh Temperature | Up to 35'C |

| Design Pressure | Up to 5 Kg |

| Measuring Range | 2.5 to 15000 LPH of Water |

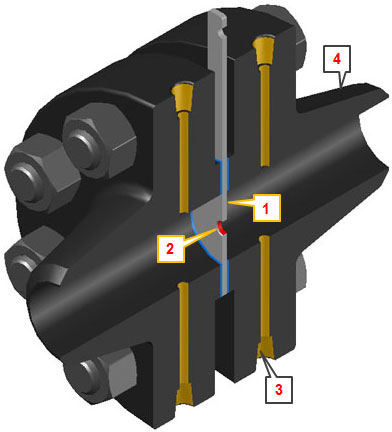

ORIFICE PLATE

Orifice plates are one of the most popular devices for the measurement and control of fluid flow. The shape and manufacturing tolerances of plates used in measurement applications are defined in the international standardization publications of ISO, AGA, ASME and others. From the formulas and data within these publications, the relationships and values of flow, differential pressure, and plate bore are determined.

In flow control applications, orifice plates are used as restriction devices to regulate fluid flow or reduce the flowing pressure downstream of the orifice plate. The use of a fixed restriction orifice can be beneficial and economic by reducing the demands on other flow system components.