- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Heat Exchanger Manufacturers, Suppliers, Exporters in India, Pune, Kolkata, Orissa, Jharkhand, Bangalore, Chennai, Telangana

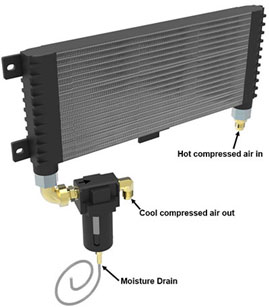

Our company “Perfectplus Engineering India Pvt. Ltd.” is one the leading Heat Exchanger Manufacturers, Suppliers, Exporters in India, Pune, Kolkata, Orissa, Jharkhand, Bangalore, Chennai, Telangana. Heat Exchanger is a kind of device or system which is used for transferring the amount of heat between two or more numbers of fluids. These exchangers are suitable and used in both processes of heating and cooling.

They are used for transferring the thermal or heat energy from one kind of fluid may it be gas or liquid to another fluid. This transferring fluid or media is separated by a solid wall or radiator for preventing mixing of it or the direct contact between the two.

Exchanger Offered By Our Company

Our Heat Exchanger manufacturer company in Pune creates wide variety of these exchangers of various different types namely as:

- Double Pipe heat exchanger

- Plate heat exchangers

- Shell and tube heat exchangers

- Condensers

- Boilers

- Evaporators, etc.

that are to be chosen by our clients as per their unique requirements.

We Heat Exchanger suppliers in Pune provide the exchangers made from different kinds of raw materials that are aluminium and copper to be chosen by our clients regarding their needs.

Features

- Accurate Heat Exchange

- Maintains Uniformity of Temperature

- Does not Relies on Additional Equipment

- Saves Energy

- Less Pollution Causing

- High Thermal Conductivity

Our shell and tube heat exchangers are used in many comfort and industry applications for heating and cooling fluids. They consist of a shell with traditional plain tubes or enhanced surface tubes for high thermal performance. The fluids can be liquids or gases, one of which flows inside the tubes while the other flows outside the tubes within the shell. There are single-phase or two-phase heat exchangers, and the latter is used to either boil or condense fluids.

| Usage/Application | Industrial |

| Material | MS, COPPER AND STAINLESS STEEL |

| Brand | Perfectplus Engineering India Pvt. Ltd. |

| Medium Used | OIL, WATER & AIR |

| Country of Origin | Made in India |

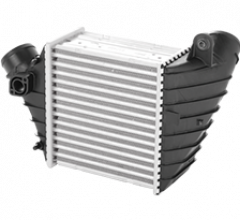

INTERCOOLER

The intercoolers (Charge Air Coolers) are designed to reduce fuel consumption while increasing the engine power and efficiency. The intercooler’s task is to reduce the temperature of the inlet gas and thus densify the air required which optimises the combustion. The intercooler lowers the temperature of the inlet gas from 130° C to 60° C, removes the negative effects of the turbo and increases the power by around 20%.

TUBE BUNDLE

A hot fluid is pumped through the bundle in a straight line from one end of the outer casing to the other.

To determine the number of tubes in this tube bundle, simply count the tubes manually.

This configuration is often popular because it involves lower installation costs.

How do you Clean Tube Bundles?

Tube bundles are easy to clean.

To clean tube bundles, you must remove them from inside the heat exchanger system.

You then clean the inside and exterior surface using suitable fluids before returning them back the device.

Cleaning of the tube bundles is possible if done chemically.

You can flash the chemical cleaning agent at high pressures directly into the inner walls of the tube bundles.

It removes any residues which could have stuck to the component.

Following this, you rinse the tubes very well so that it is clean before operation reconvenes.

In the event that there are leftover residues, the damage can be destructive to the material of construction as well as potentially contaminate the fluid/product.

Similarly, you can clean the insides of the tube bundles mechanically.

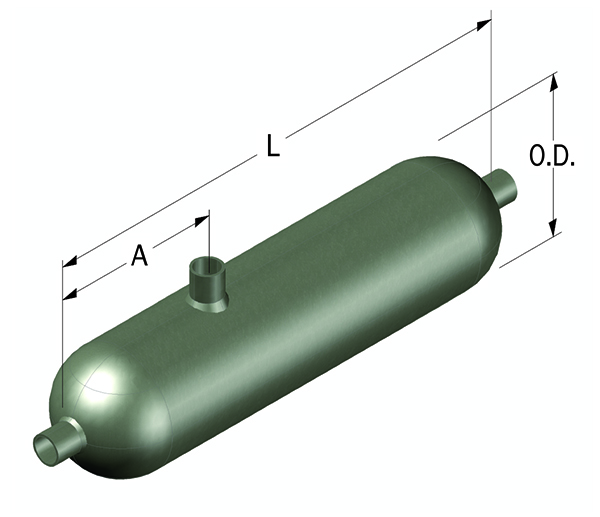

CONDENSATE SEAL POT

Condensate chambers, also known as seal pots and condensate drip pots, are welded pressure vessels that allow instruments and valves to be attached in line with routed tubing to allow for line sampling, elimination of fluid, and other processes. They are used to protect sensitive metering systems and devices by trapping and holding condensate and foreign material that may accumulate in gaseous service lines.