- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Vacuum Ejector System Manufacturers/Suppliers/Exporters in India

Perfectplus Engineering India Pvt. Ltd. is a leading manufacturers, suppliers, exporters of vacuum ejector system in India with over 8 years of experience. We are Vacuum Ejector System manufacturers. Suppliers and exporters in India provide a wide range of variety at affordable prices, and the latest designs have made them popular among their clients.

We vacuum ejector system have been providing the best quality products to its customers since the year 2014 and have been recognized as one of the best companies in the field of engineering and manufacturing by many organizations around the globe. We have been providing high-quality products at the most competitive rates to our customers.

The vacuum ejector system offers the best quality and perfect engineering solutions at affordable prices to its customers. We provide high-performance technology for water treatment plants with an innovative range of designs and a huge range of variety.

Introduction-

Vacuum ejector system is a device that sucks the air out of the container and then releases the container. The process of vacuuming the air out of a container is called vacuum ejection.

The most common use of this device is in industrial applications, such as in factories and refineries. However, it can be also used for other purposes like water-jet cutting and sanding wood. It is an automated, high-speed, and reliable method for removing air from vessels. This system can be installed in any size or shape vessel which is why it is popular in many industries.

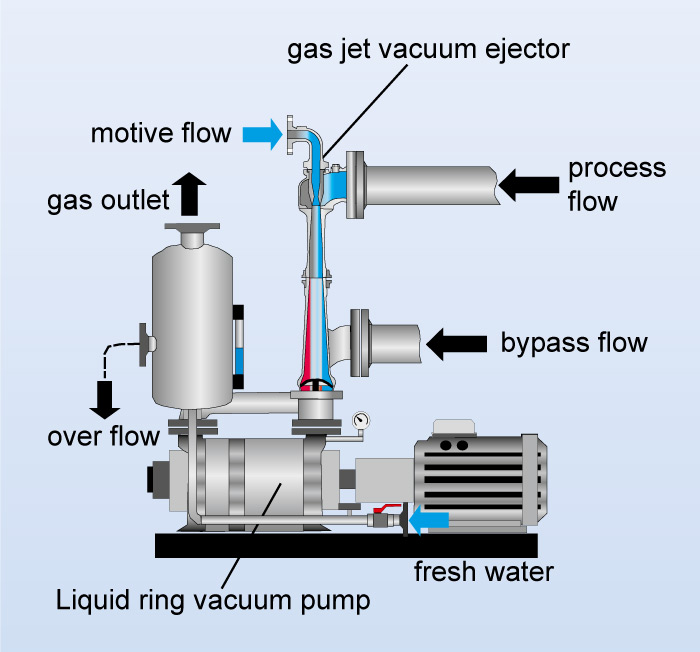

The components of Vacuum ejector systems include a suction pump, suction head, air compressor, air hose, control valve, filter, and piping.

Features:

- The device can be easily installed on-site without requiring any additional infrastructure or modifications.

- The vacuum ejector system allows for quick and efficient transportation of waste from one place to another.

- It has been designed for operation at low pressure, making it suitable for use in confined spaces.

- All components are made of corrosion-resistant materials that are optimized to resist the harsh conditions associated with waste transportation.

Benefits-

The vacuum ejector system is a great tool that can help you get rid of all the dust and debris in your home. It's easy to use and doesn't require any maintenance so you don't have to worry about it breaking down over time.

The benefits of using vacuum ejectors are:

- It is easy to use.

- It doesn’t require any power source.

- It does not produce any noise during operation

- Quick cleaning and Low maintenance required

Application:

Vacuum ejector systems are used in various industries such as manufacturing, aerospace, food processing, and even construction. It can be used to create pressure differentials on the inside of the vacuum chamber which results in air being pulled out of the chamber.